Prefabricated laminated 3ply or more on the

thickness door and window Eucalytus and Hemlock scantlings.

Highest quality hardwood and softwood timber,

free from all defects. Main species are Eucalytus and Hemlock but

we can also work in other materials you need.

At DENO, we manufacture premium Enculyptus / Hemlock window scantlings that meet the highest joinery standards. We use carefully selected, high-density timber to ensure excellent dimensional stability and resistance to warping.

Our production process includes advanced finger-jointing, precise planing, and custom lamination — all under strict quality control. One of our core technologies is thermal modification (carbonization), which enhances durability and weather resistance. Products can be supplied either carbonized or non-carbonized, depending on your specific needs.

Looking for reliable, high-performance materials for window scantlings? DENO has the solution.

The composition of the scantlings can be: Lamellas without finger joint are identified by the letter “D” and lamellas with finger joints by “K”.

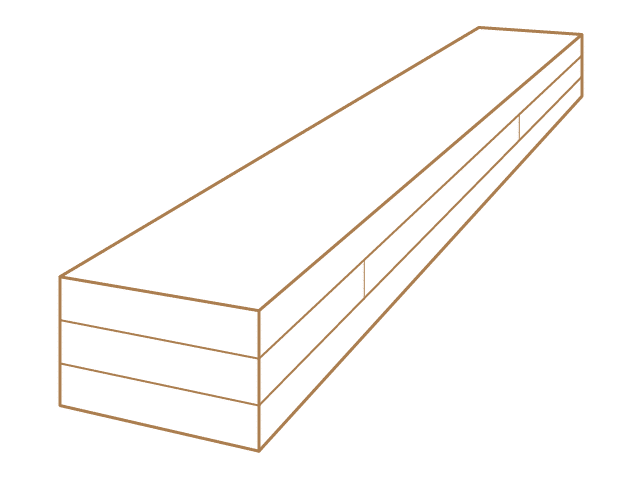

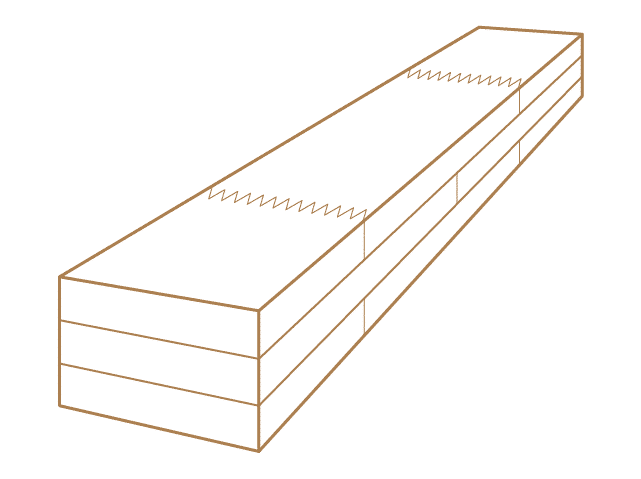

SCANTLING DKD

Three or more solid lamellas glued together until reaching the required thickness; standard lengths from 600 to 4500mm or 5100mm , depending on the wood species.

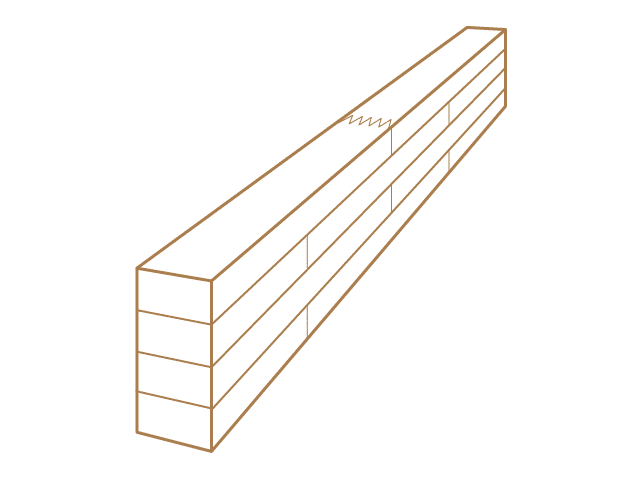

SCANTLING KKK

Three or more solid lamellas glued together until reaching the required thickness and length; standard lengths 6000mm.

SCANTLING FOR CURTAIN WALL

The wooden curtain wall is a mixed wood-glass structure that functions structurally as a single element. It is an innovative façade concept that makes it possible to create light and very luminous structures that make design and environment compatible.

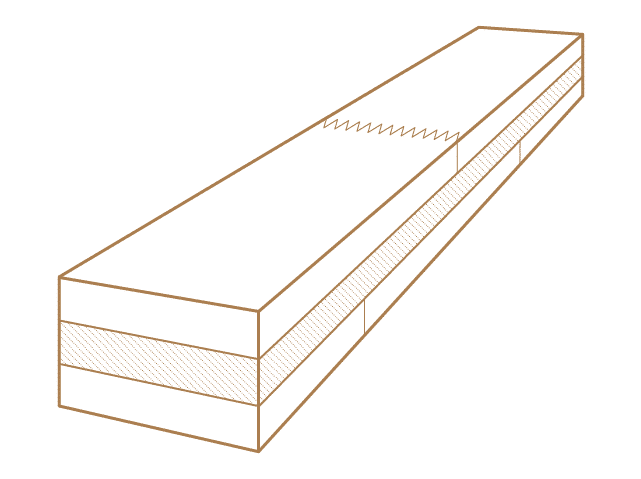

HIGH PERFORMANCE SCANTLINGS

Laminate scantlings whose insulating and/or acoustic properties have been improved by incorporating combinations of different materials in their composition

Window scantlings – technical information

TYPE OF WOOD

Eucalyptus /Hemlock

HUMIDITY

6%-12%

GLUE TYPE

D4, EPI

QUALITY

1st Grade

CRAFT

Solid or Glued

We offer fixed window scantlings of the following dimensions:

Other windows scantlings

Finger-jointed tangential (T/T/T) window scantlings.

Non-standard dimension window scantlings.

Custom dimensions and scantling constructions (like L and Z profiles) are available.

For additional information – please contact us.

How DENO window scantlings are made?

At DENO, we are equally dedicated to producing high-quality thermally modified window scantlings.

We start with carefully selected solid wood and apply a high-temperature thermal treatment—completely chemical-free—to enhance moisture resistance, decay resistance, and dimensional stability.

After thermal modification, the wood is processed into lamellas, then finger-jointed and laminated as needed. Every production step is subject to strict quality control, ensuring the final products perform exceptionally in window joinery applications.

Window Scantlings – durability and precision

To guarantee maximum strength and resistance to external conditions, our window scantlings are bonded using high-quality D4 and EPI adhesives.

D4 glue:

water-resistant and weatherproof;

ideal for bonding wooden and wood-based components;

fills gaps, creating a smooth and uniform surface.

Epi Glue:

provides exceptional bond durability;

moisture-resistant, reducing the risk of swelling and delamination;

enables bonding of timber with higher moisture content (15–16%).

Scantlings Album